Metal Shop

The machinery line-up for the metal shop is:

- Enco 12x36 lathe

- Enco 9x20 lathe

- Central Machinery 7x10 lathe

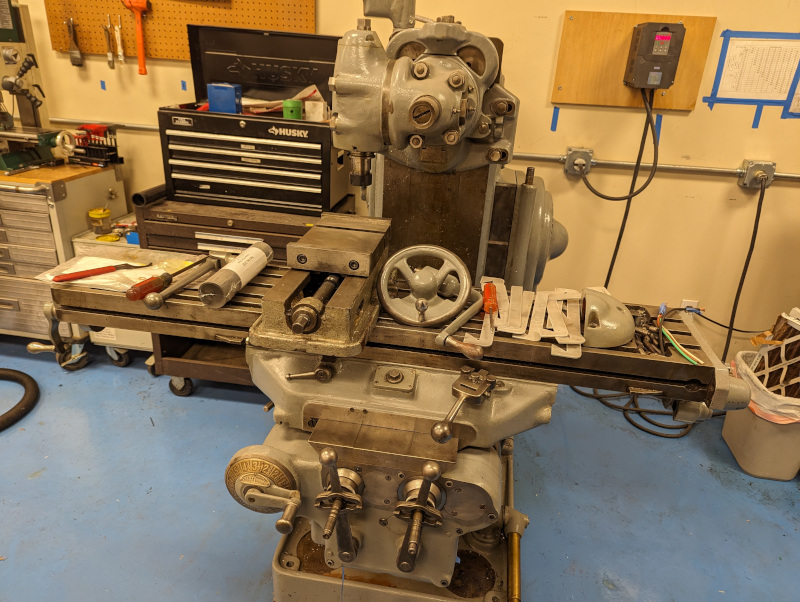

- K&T 2H mill

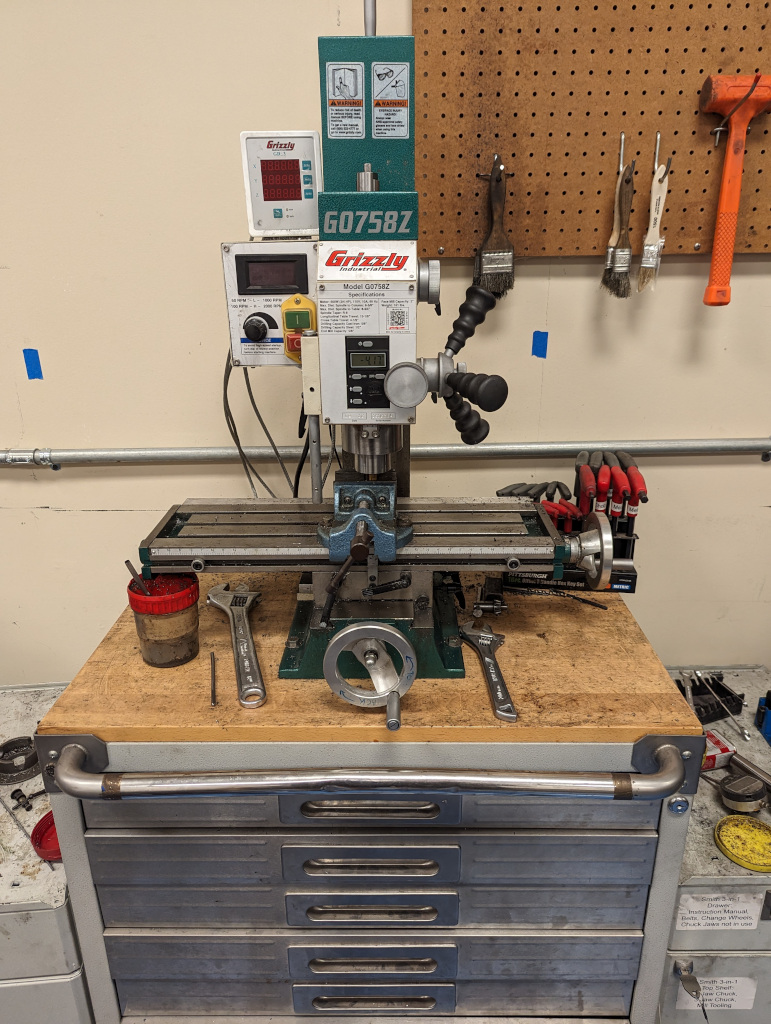

- Grizzly G0758Z mill

- Dedicated cold work bench (iron worker, bench vise, ring roller, brakes)

- General purpose work bench

- Welding, cut-off, and grinding area

Lathe: Enco 9x20

This is one of the fairly ubiquitous import 9x20 lathes. There’s plenty of documentation on the internet example. We have a reasonably complete set of tooling, including:

- 4" 3-jaw self-centering chuck, with inside and outside jaws (!)

- 8" 4-jaw independent chuck

- 7.5" faceplate

- Steady rest

- Follower rest

- 4-way toolpost

- Dorian AXA quick-change toolpost

- Tailstock chuck

- Live and dead centers

The 9x20 is a fairly competent small lathe. It’s got a half of a quick change gear box–there are 9 QC settings, but to get the full range of 27 English and 18 Metric threads, as well as two power feed speeds, takes some manual gear swaps. It cannot do left-hand threads, and there’s no backgear or power cross-feed (common features on some larger lathes). The lathe is in very good shape, except that the tailstock handwheel has been previously broken and imperfectly repaired, so the tailstock travel isn’t graduated, nor is there as much travel as there should be.

A good reference for the 9x20 lathes is Colin Feaver’s Introduction to 9x20 Lathe Operations.

Note that the motor on this lathe is not original (the original motor failed in the spring of 2021.) Because the original motor had a funky, not-quite standard set of dimensions, mounting the new motor shifted the pulley positions and the original tensioner that let us use the same belt for two different speed ranges no longer works, and you have to change belts between the high and low speed ranges. Finding a new mounting geometry to restore the single-belt tensioning arrangement is on the round tuit list, but not very high priority at the moment.

Wishlist:

- 5/16" tool bits, HSS

- 5/16" inserted carbide tool bits (CCMT or TCMT)

- AXA QC toolholders (we have a mongrel collection of QC toolholders, most of them seem to be BXA for the Smithy)

- Lathe dog

Lathe: Enco 12x36

This lathe is under repair (the drive worm in the carriage got stripped.)

Mill: Kearney & Trecker 2H with vertical head

On loan from a member. Please treat it carefully. Recently upgraded with a DRO. Beware: the spindle currently has more runout than it’s owner is happy with (3-5 10thou) and the issue is being investigated. Please attend a metal shop open house before using.

Mill: Grizzly G0758Z

This is a 6x20 tabletop mill. Collets and tooling for the mill live in the drawers underneath. Please keep the tooling together with the mill and put tools back where you got them when you’re done.

Bandsaw: Grizzly G4030 6.5“x10” Horizontal Bandsaw

Welder: Century 160 Mig Wire Feed Welder

It’s set up with 0.030" ER70S wire and CO2/Ar gas.

Grinding Bench

Cold Working

Iron worker, ring roller, brakes