3D Printers

3D Printers

| How to Use the 3D Printers | |

|---|---|

| There are several steps when creating a finished 3D printed product at the makerspace: 1. Create or find a 3D model – Design in Fusion 360, SolidWorks, TinkerCAD, or FreeCAD, or download from Thingiverse, MakerWorld, Printables, or MyMiniFactory. 2. Slice your model – Convert .stl, .3mf, or .obj into .gcode using Bambu Studio, PrusaSlicer, Cura, or Chitubox. 3. Send to printer – Transfer G-code via SD card, USB, or network (for Bambu printers). 4. Monitor the print – Ensure first-layer adhesion and proper extrusion or resin exposure. 5. Post-process – Remove supports, clean the area, and finish your model. 6. Weigh and Pay – $0.05/g for FDM, $0.10/g for SLA prints using makerspace materials. |

|

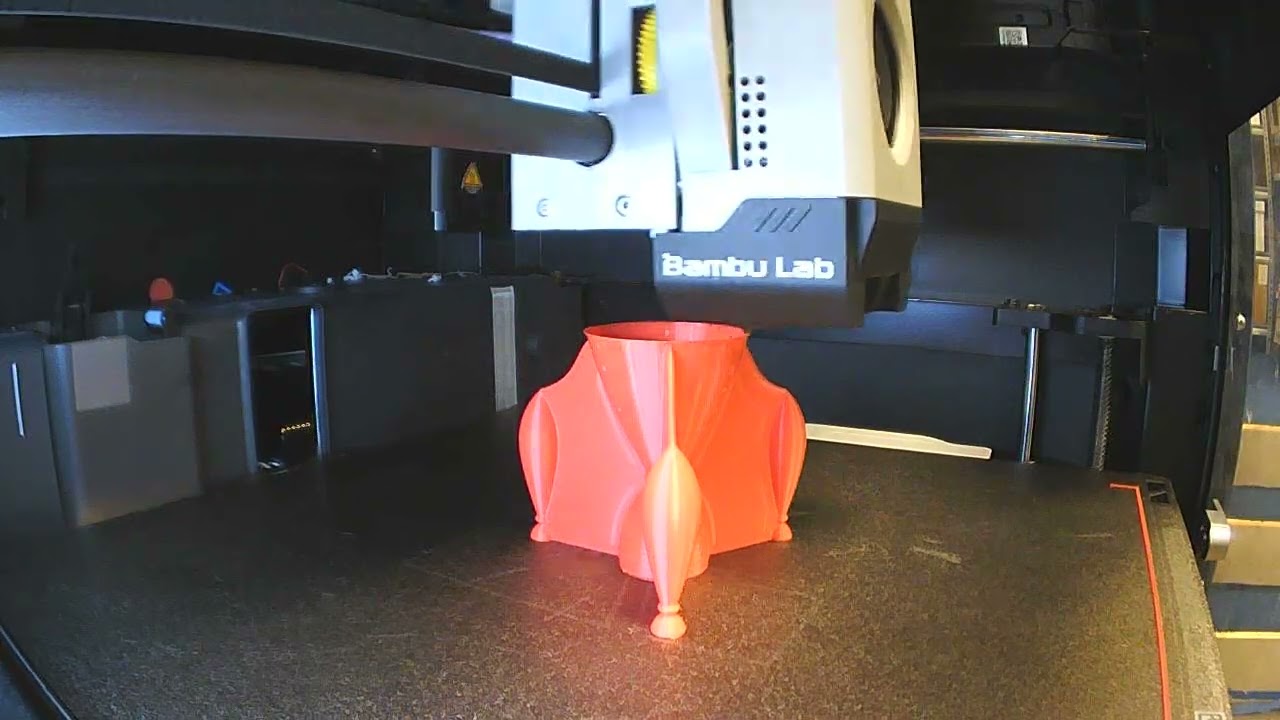

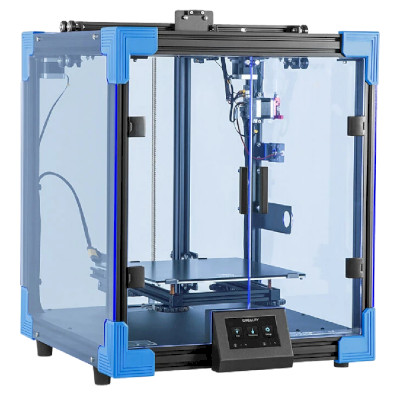

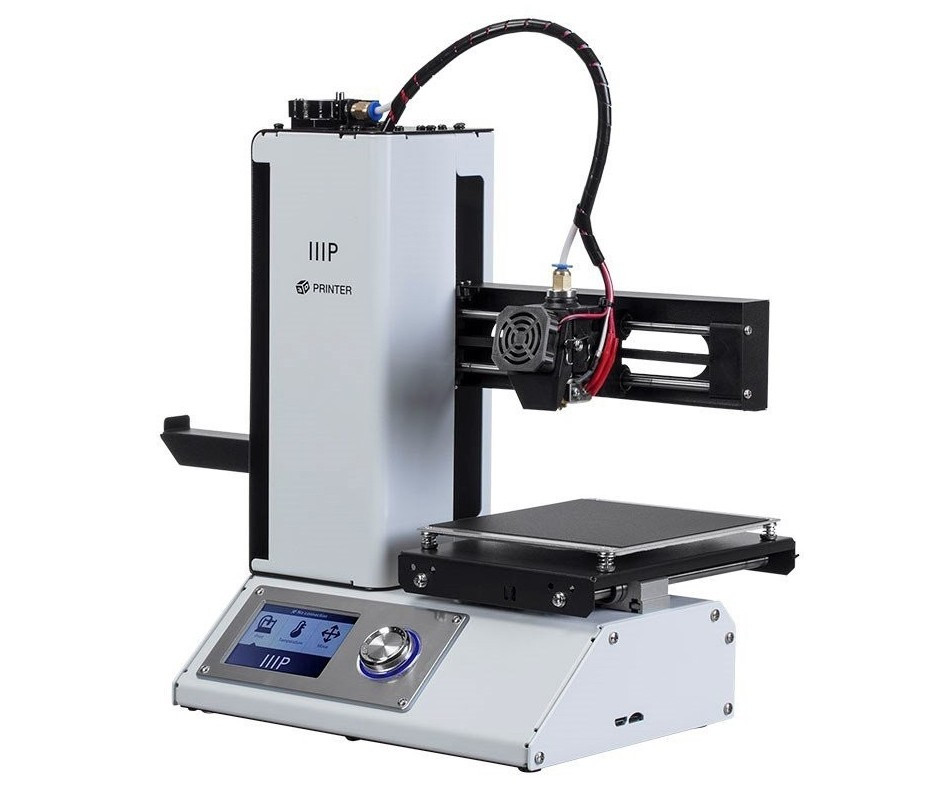

FDM / Extrusion Printers

Fused Deposition Modeling (FDM) — also known as Fused Filament Fabrication (FFF) — is the most common form of 3D printing.

These machines melt thermoplastic filament and deposit it layer by layer to form a solid object.

At the makerspace, we use FDM printers for durable parts, enclosures, and mechanical prototypes.

All FDM prints using makerspace filament are priced at $0.05 per gram.

| Printer | Bambu P1S + AMS 2 Pro (Left) | Bambu P1S + AMS 2 Pro (Right) | Creality Ender 6 | Creality CR-10 V3 |

|---|---|---|---|---|

| Image |  |

|

|

|

| Print Volume | 256 × 256 × 256 mm | 256 × 256 × 256 mm | 250 × 250 × 400 mm | 300 × 300 × 400 mm |

| Heated Bed | Yes | Yes | Yes | Yes |

| Filament Diameter | 1.75 mm | 1.75 mm | 1.75 mm | 1.75 mm |

| Nozzle Diameter | 0.4 mm (swappable) | 0.4 mm (swappable) | 0.4 mm | 0.4 mm |

| Layer Height Range | 0.08 – 0.28 mm | 0.08 – 0.28 mm | 0.1 – 0.4 mm | 0.1 – 0.4 mm |

| Supported Materials | PLA, PETG, ABS, ASA, TPU, PA | PLA, PETG, ABS, ASA, TPU, PA | PLA, PETG, ABS | PLA, PETG, ABS, TPU |

| Auto Bed Leveling | Yes | Yes | Semi-Auto | Manual |

| Multi-Material Support | 4-spool AMS 2 Pro | 4-spool AMS 2 Pro | No | No |

| Connectivity | Wi-Fi / LAN / MicroSD | Wi-Fi / LAN / MicroSD | SD Card / USB | SD Card / USB |

| Software | Bambu Studio / OrcaSlicer | Bambu Studio / OrcaSlicer | PrusaSlicer / Cura | PrusaSlicer / Cura |

| Status | 🟢 Fully Operational | 🟢 Fully Operational | 🟠 Under Repair (Likely Motherboard issue) | 🟢 Fully Operational |

| Notes | Enclosed CoreXY printer (up to 500 mm/s) | Same as Left unit, often used for multi-color jobs | Enclosed cube printer; currently offline | Reliable large-format printer |

| Documentation | Bambu P1S | Bambu P1S | Ender 6 | CR-10 V3 |

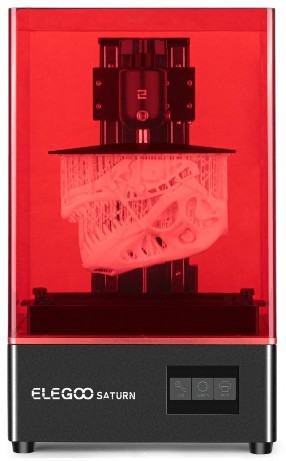

SLA / Resin Printers

Stereolithography (SLA) and Masked SLA (MSLA) printers use UV light to cure liquid resin one layer at a time,

producing parts with extremely fine detail and smooth surfaces.

At the makerspace, SLA printing is ideal for miniatures, molds, and detailed prototypes.

SLA prints using makerspace resin are priced at $0.10 per gram.

Resin Printer/SLA usage, cleaning, and workflow

| Printer | Prusa SL1S SPEED | Elegoo Saturn 1 |

|---|---|---|

| Image |  |

|

| Print Volume | 127 × 80 × 150 mm | 192 × 120 × 200 mm |

| Display | 5.96″ mono LCD (2560×1620) | 8.9″ mono 4K LCD |

| Layer Height Range | 0.025 – 0.1 mm | 0.05 – 0.15 mm |

| Technology | MSLA (Masked Stereolithography) | MSLA (Masked Stereolithography) |

| Materials Supported | UV-sensitive resins | UV-sensitive resins |

| Curing Wavelength | 405 nm | 405 nm |

| Software | PrusaSlicer (SLA mode) | Chitubox / Lychee |

| Connectivity | LAN / USB | USB |

| Status | 🟢 Fully Operational | 🟢 Fully Operational |

| Notes | High precision, fast exposure times | Great for medium-to-large resin prints |

| Documentation | SL1S SPEED | Elegoo Saturn |

Friendly Printer Usage

- Share the printers: During high-usage hours, please use one printer at a time so everyone gets access.

- Be mindful of queue length: For long jobs (>8 hrs), consider off-peak times or split into smaller parts.

- Filament storage: Return open spools to sealed dry boxes after use.

- Vacuum-sealed spools: Store vacuum-sealed filament on the rack above the FDM printers. Do not open unless needed.

- Resin handling: Cap bottles, clean drips immediately, and keep resin in approved containers only.

- Weigh & pay fairly: Weigh all completed prints, including supports and failed prints, and pay:

- FDM: $0.05/g (makerspace filament)

- SLA: $0.10/g (makerspace resin)

- Cleanup is part of the job: Vacuum the floor around the printers, wipe the tables, and leave the area free of debris or resin spills.

- Log issues: If a printer misbehaves (clogs, layer shift, adhesion problems), note it on the printer log and send a message using Report a Problem

Tool Masters

| Name | Role | Contact |

|---|---|---|

| Glenn Miller | 3D Printing Tool Master | [Add Contact Info] |

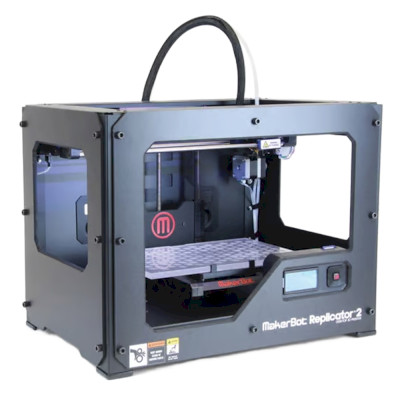

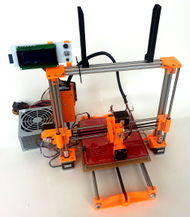

Former Printers

| Printer | Image | Print Volume | Supported Materials | Heated Bed | Status | Notes | Documentation |

|---|---|---|---|---|---|---|---|

| DeltaMaker 2 |  |

240 × 260 mm | PLA only | No | 🔴 Retired | PLA-only delta printers (3 units). | DeltaMaker Support |

| AnyCubic Predator |  |

370 × 455 mm | PLA, PETG | Yes | 🔴 Retired | Large-format delta printer, discontinued. | N/A |

| Ender-5 Plus |  |

350 × 350 × 400 mm | PLA, PETG | Yes | 🔴 Retired | Large Bowden printer replaced by Bambu units. | Ender-5 Plus |

| Makerbot Replicator 2 |  |

285 × 153 × 155 mm | PLA only | No | 🔴 Retired | Legacy small build area printer. | Makerbot Manual |

| Monoprice Select Mini V2 |  |

120 × 120 × 120 mm | PLA | Yes | 🔴 Retired | Compact beginner printer. | MP Select Mini Manual |

| RepRap Wilson TS (Super Jojo) |  |

Custom | PLA, PETG, ABS | Yes | 🔴 Dismantled | Community-built RepRap project. | RepRap Wiki |

categories: tools